What started as a simple errand to deposit a check at a bank drive-through became the kind of “aha” moment found mostly in books and movies.

Georgia Tech researchers had been working on an idea to simplify traditional direct air capture (DAC) systems. Their approach used ambient wind flow to draw air across a new kind of coated carbon fiber to grab CO2. That would eliminate the loud fans used in many systems. And the carbon fiber strands could be quickly heated to release the captured carbon dioxide with minimal heat loss, boosting efficiency.

But they were struggling with how to deploy these new sorbent-coated carbon fibers for maximum effect.

“I had to go deposit a check at the bank, and I went through the drive-through. They had the old pneumatic tubes that come down to transport documents,” said Ryan Lively, Thomas C. DeLoach Professor in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE). “There are not many times you have a light bulb moment in your career, but I saw the tubes and I realized, we could put the fibers in something like a bank teller tube canister.

“That’s pretty much what we did, and it worked.”

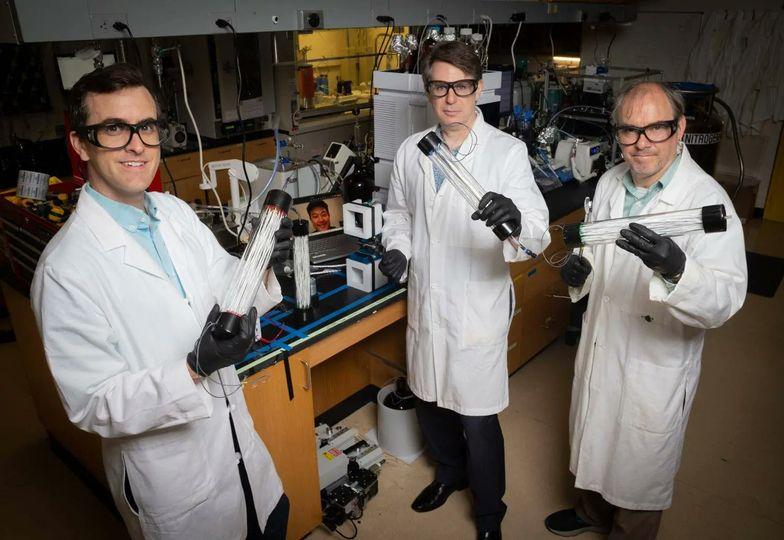

Ryan Lively, Won Hee Lee (on laptop), Christopher Jones, and Matthew Realff developed the fiber-based DAC system.