Professor William Koros

Gas separations can play an important role in reducing carbon footprints and mitigating the environmental impacts of industrial activities, according to William Koros, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering.

While membrane-based separation processes have shown promise in reducing energy consumption, achieving optimal efficiency has remained a challenge, Koros said.

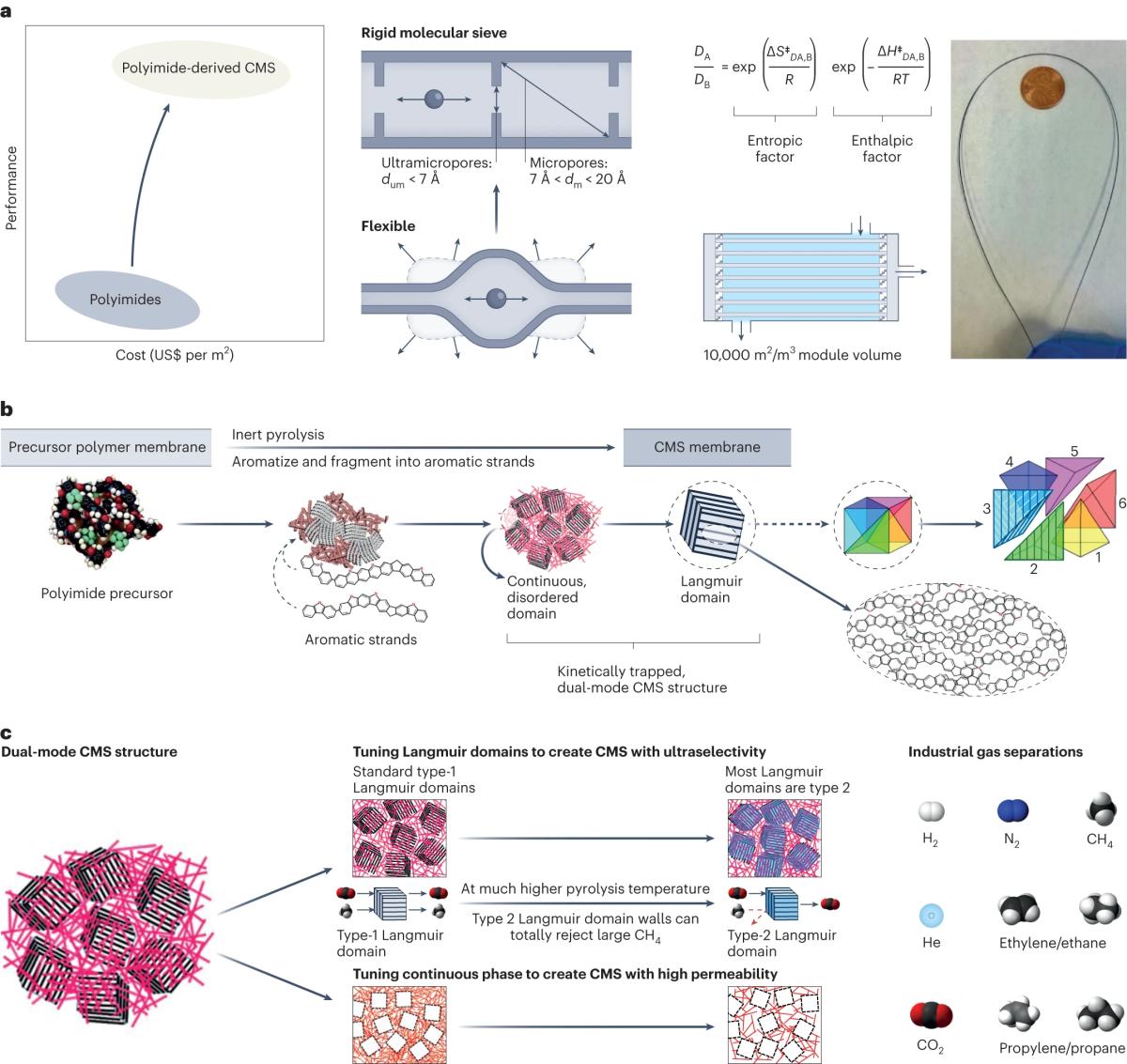

He and his collaborators (research scientists Zhongyun Liu and Yuhe Cao) recently showed that polyimide-derived carbon molecular sieve (CMS) membranes could significantly improve energy-intensive separations, offering enhanced efficiency and sustainability.

“By combining exceptional selectivity with scalability and affordability, these membranes have the potential to drive significant advancements in energy transition efforts worldwide,” said Koros.

The researchers, who recently published their findings in Nature Chemical Engineering, found that CMS membranes demonstrate favorable mechanical properties, making them suitable for industrial applications. In addition, they offer stable gas permeability and selectivity, enhancing their practicality for real-world use.

The membranes exhibit tunable discrimination between gas molecules at ångström-level precision, due to their unique bimodal pore size distributions. These membranes feature large micropores for high sorption capacities and ultramicropores for molecular sieving selectivity, presenting improved separation performance compared to conventional materials.

The research highlights the importance of engineering CMS membranes to optimize their structure and performance. Through molecular engineering of precursors and precise control of pyrolysis conditions, researchers showed that the membranes could be tailored to specific gas separation tasks, offering customizable solutions for various industrial applications.

By utilizing low-cost precursors and innovative manufacturing techniques, the researchers reduced material costs without compromising performance. This breakthrough has the potential to transform gas separation processes across various industries, Koros said.

Moving forward, the researchers anticipate further advancements in CMS membrane technology, aiming to address even more complex separation challenges. Continued refinement of manufacturing processes and exploration of new precursor materials aim to unlock the full potential of CMS membranes for a sustainable future.

Citation

Zhongyun Liu, Yuhe Cao & William J. Koros, “Polyimide-derived carbon molecular sieve membranes for gas separations,” Nature Chemical Engineering (2024), https://www.nature.com/articles/s44286-023-00021-1

Key features and engineering of CMS membranes for industrial gas separations